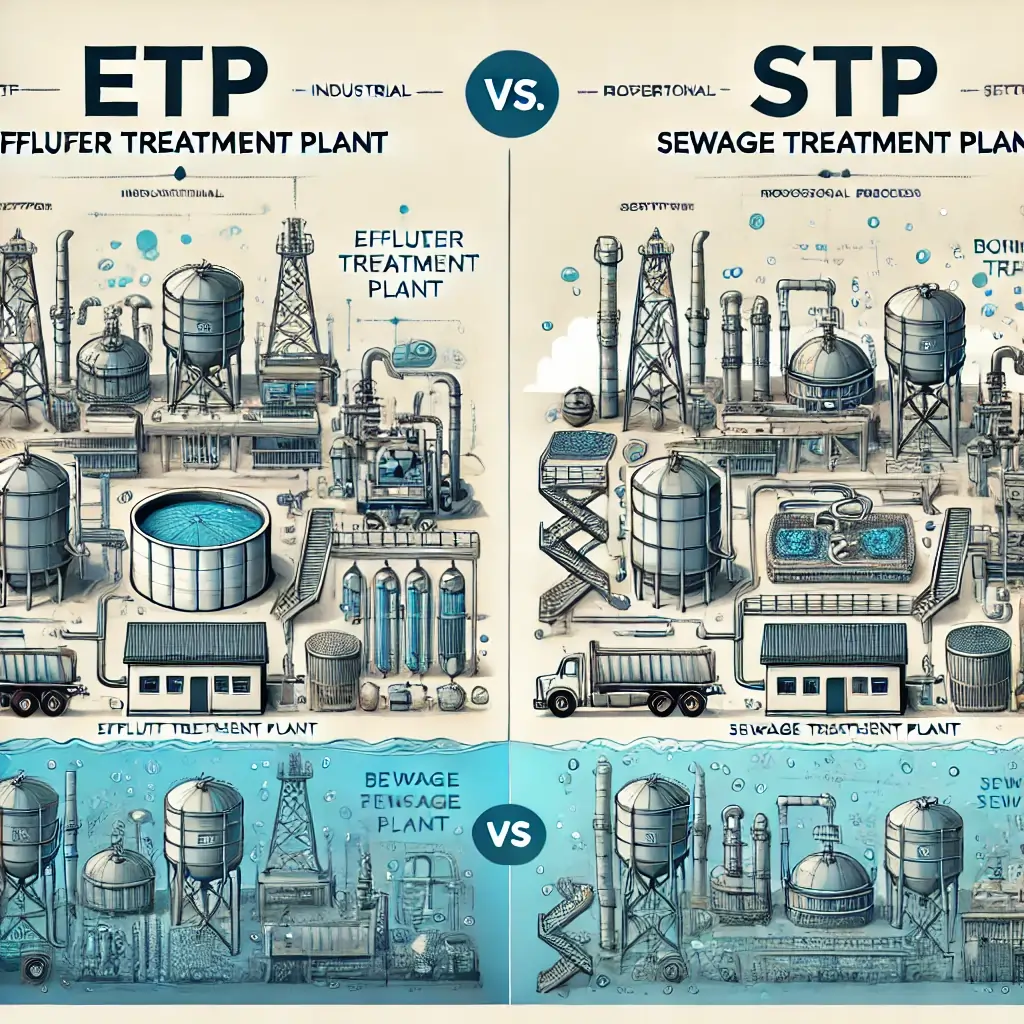

Difference Between Effluent and Sewage Treatment Plants

Effluent Treatment Plants (ETP) and Sewage Treatment Plants (STP) are both essential for water treatment, but they serve different purposes and industries. At Unistar Aquatech Private Limited, we provide cutting-edge solutions for both ETP and STP, ensuring compliance with environmental standards.

ETP is primarily designed to treat industrial wastewater generated from factories, manufacturing units, and chemical processes. It focuses on removing toxic contaminants such as heavy metals, chemicals, and oils to make the water safe for disposal or reuse. Advanced techniques like chemical coagulation, filtration, and reverse osmosis are often employed in ETP systems.

STP, on the other hand, is meant to treat domestic sewage from residential, commercial, and municipal sources. Its primary goal is to remove organic matter, solids, and pathogens to produce clean water suitable for irrigation, flushing, or safe discharge. Processes like biological treatment, aeration, and disinfection are commonly used in STPs.

While both systems contribute to environmental conservation, ETP addresses complex industrial waste, whereas STP focuses on domestic wastewater. Choosing the right system depends on the source and type of wastewater. At Unistar Aquatech, we specialize in customizing solutions for your specific requirements, ensuring efficiency and sustainability in water management.

Waste Characteristics and Treatment Requirements

- Composition of Industrial Wastewater: The chemical makeup of wastewater produced by industrial activities varies. Effluents from manufacturing facilities contain chemical compounds and heavy metals. Cleaning agents and garbage with a high organic content are produced by the food processing industry. Wastewater that contains bleaching chemicals and dyes is a problem for textile makers. Depending on the raw materials and production cycles, the waste composition varies.

- Properties of Domestic Sewage: The composition of domestic sewage exhibits regular trends. There is organic stuff from human activity in this effluent. The organic load in sewage systems is increased by food waste. The chemical composition of household trash is influenced by cleaning agents. During peak hours, the waste flow stays constant throughout the day.

- Treatment Goals: Environmental laws establish precise standards for the quality of treated water. Before releasing hazardous materials, industries must remove them. Safe disposal requirements should be met by the treated water. Reusing treated water in their operations is the goal of several enterprises. Different technical approaches are required for each therapeutic target.

Comparing Treatment Technologies

- ETP Treatment Methods: To treat industrial waste, ETPs use both chemical and physical processes. Through settlement tanks, suspended solids are eliminated during primary treatment. Hazardous materials in the water are neutralized by chemical treatment. Complex organic molecules are broken down via advanced oxidation. Membrane filtration guarantees that the final water quality is up to par.

- STP Biological Processes: STPs concentrate on biological approaches to organic waste treatment. In aeration tanks, organic matter is broken down by aerobic bacteria. Concentrated organic waste is handled by anaerobic digestion. Water pollution in natural bodies is avoided through nutrient removal. In response to shifting waste loads, the biological systems adjust.

- Technology Integration: To improve outcomes, contemporary healthcare facilities integrate various technologies. Continuous monitoring of treatment procedures is done via automated control systems. Water quality characteristics are measured via online sensors. Data analytics maximizes the effectiveness of treatment. Integration enhances system performance as a whole.

Operational Considerations and Cost Analysis

- Operation Requirements: To oversee chemical operations, ETPs require knowledgeable operators. Proper treatment efficiency is ensured by routine monitoring. Operators have to modify settings according to the properties of the trash. Safety procedures shield employees from exposure to chemicals. Plans for emergency response deal with malfunctioning equipment.

- Maintenance Requirements: The health of the biological system is the main focus of STP maintenance. Equipment blockages are avoided with routine cleaning. Treatment effectiveness is guaranteed by bacterial culture management. System performance is maintained through sludge removal. Breakdown chances are decreased by preventive maintenance.

- Cost Components: Equipment and installation fees are included in the initial setup costs. Chemicals and electricity use are included in operating costs. Labor costs and replacement parts are included in maintenance costs. Maintain systems up to date with new standards and upgrade expenses. Operating costs are increased by staff training.

- Return on Investment: Treatment expenses are mitigated by prospects for water reuse. Equipment life is increased by proper maintenance. Power consumption is decreased by efficient activities. Penalty fees are avoided by compliance. Business operations are made more valuable by environmental benefits.

Take Action for Better Wastewater Treatment: Choose the right wastewater treatment solution for your industry today. Our experts will help you evaluate whether an ETP or STP system suits your needs best. We analyze your wastewater characteristics and recommend the most effective treatment solution. Contact us now to schedule a detailed assessment of your industrial wastewater treatment requirements.

Contact Unistar Aquatech Private Limited at: Phone: +91-9811701883, 8588881234, Email: india@unistaraquatech.com.