What is Transmembrane Pressure (TMP)?

Transmembrane Pressure (TMP) is a crucial concept in filtration processes, particularly in membrane technologies like reverse osmosis (RO), ultrafiltration (UF), and microfiltration (MF). It plays a significant role in ensuring the efficiency and effectiveness of water treatment systems. In this blog, we will explore what TMP is, why it is important, and how it applies to filtration systems.

Understanding Transmembrane Pressure

Transmembrane Pressure refers to the pressure difference across a membrane, which drives the movement of water or solutes through the membrane. This pressure enables the separation of contaminants, impurities, or particles from the fluid being treated. Essentially, TMP is the driving force behind the filtration process.

Formula for TMP:

The formula to calculate Transmembrane Pressure is:

Where:

- Feed Pressure: The pressure of the fluid entering the membrane system.

- Concentrate Pressure: The pressure of the fluid exiting the system (reject or concentrate stream).

- Permeate Pressure: The pressure of the filtered water (permeate).

This calculation helps monitor and control the filtration process, ensuring optimal system performance.

Why is TMP Important?

1. Performance Monitoring:

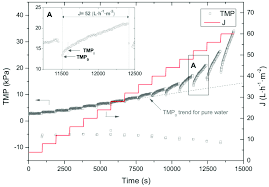

A stable TMP indicates that the system is operating efficiently. A rising TMP can signal issues like fouling, scaling, or clogging of the membrane, which require immediate attention.

2. System Optimization:

TMP serves as a key parameter to optimize the filtration process. Adjusting TMP ensures maximum filtration efficiency and prolongs membrane lifespan.

3. System Design:

TMP is a critical factor in designing membrane systems. Engineers consider TMP when selecting membranes and setting operational parameters for specific applications.

Applications of Transmembrane Pressure

1. Water Treatment: TMP is extensively used in reverse osmosis and ultrafiltration systems for desalination, wastewater treatment, and producing potable water.

2. Pharmaceutical Industry: Membrane filtration with controlled TMP is essential for sterile filtration, protein separation, and other pharmaceutical processes.

3. Food & Beverage Industry: TMP helps ensure high-quality filtration in processes like juice clarification, dairy filtration, and brewing.

Maintaining Optimal TMP

To ensure efficient operation of membrane systems, regular monitoring and maintenance are essential. Here are some tips:

- Routine Cleaning: Periodically clean the membranes to prevent fouling and scaling.

- Monitor TMP Trends: Keep an eye on TMP readings to detect any sudden changes.

- Use Quality Feed Water: Pretreatment of feed water can reduce the risk of contamination and scaling.

At Unistar Aquatech, we specialize in designing and maintaining advanced water treatment systems, ensuring optimal TMP and long-lasting performance.

About Unistar Aquatech

Unistar Aquatech is a trusted provider of cutting-edge water treatment solutions.

Contact Us:

- Phone: +91 9811701883

- Email: india@unistaraquatech.com

- Address: Plot – 106-D Anand Industrial Estate, Mohan Nagar, Ghaziabad, Uttar Pradesh, India

Enquire Now

Recent Posts

- Top 10 Water Treatment Plant Manufacturers in India

- What Is an Industrial RO Plant And How Does It Work?

- LPH in RO Water Purifier

- What is Activated Sludge Process?

- Normal TDS Level in Drinking Water

- Difference Between Effluent and Sewage Treatment Plants

- What is E20 Gasoline

- What is E20 Fuel? Benefits, Effects on Engines, and How Biofuel Supports India’s Growth

- What is Transmembrane Pressure (TMP)?

- Effluent Treatment Plant Manufacturers in Pune