Activated sludge process is a widely used and highly effective biological treatment technique in wastewater treatment plants (WWTP). This process is essential for breaking down organic matter, nutrients, and other pollutants in sewage or industrial wastewater, ensuring that the effluent released into the environment meets environmental regulations.

It is critical to understand that activated sludge is orderly to comprehend how the entire activated sludge system operates. Because the particles are actively swarming with beneficial bacteria that digest the sewage, the sludge is considered activated. In this article, we’ll explore the activated sludge process in detail, its benefits, and how it works, highlighting its significance in modern wastewater management systems.

Activated Sludge Process

The Activated Sludge Process is used in biological wastewater treatment methods that effectively removes organic pollutants from sewage and industrial effluents. It relies on microorganisms, primarily bacteria, to break down organic matter in the presence of oxygen.

In this process, wastewater enters an aeration tank, where air is continuously supplied to promote the growth of microbial flocs (activated sludge). These microorganisms consume organic matter, converting it into carbon dioxide, water, and new microbial cells. The treated water then flows into a settling tank, where the sludge settles at the bottom. A portion of the sludge is recirculated back into the aeration tank to maintain microbial activity, while excess sludge is removed for further treatment or disposal.

The Activated Sludge Process has several advantages, such as high treatment efficiency, adaptability to varying loads, and effective removal of organic and nitrogenous pollutants. However, it requires careful monitoring of oxygen levels, sludge age, and microbial activity to prevent issues like sludge bulking.

Used in municipal and industrial wastewater treatment plants, ASP plays a crucial role in ensuring clean water discharge and environmental protection, making it one of the most effective and sustainable wastewater treatment methods.

Activated Sludge Process Steps

- Influent Wastewater: The process begins when raw or partially treated wastewater enters the aeration tank. This wastewater contains organic matter, nutrients, and other pollutants that need to be removed.

- Aeration Tank: In this step, air or oxygen is pumped into the tank to promote the growth and activity of aerobic microorganisms. These bacteria metabolize organic pollutants in the wastewater, converting them into carbon dioxide, water, and new bacterial cells. This phase is critical, as it ensures that the microorganisms remain active and efficient in breaking down the waste.

- Secondary Clarifier: After the aeration tank, the treated water moves into a secondary clarifier or settling tank. In this tank, the activated sludge (biomass containing microorganisms) settles to the bottom, while the treated water rises to the top and is discharged or subjected to further treatment if needed.

- Return Activated Sludge (RAS): A portion of the settled sludge is returned to the aeration tank to maintain an optimal concentration of microorganisms. This recycled biomass is called return activated sludge (RAS), and it plays a crucial role in keeping the process continuous.

- Waste Activated Sludge (WAS): The remaining sludge, which is not returned to the aeration tank, is called waste activated sludge (WAS). This excess sludge is typically sent to sludge digestion, dewatering, or other treatment processes before final disposal.

The activated sludge process is maintaining a balanced environment for the microorganisms. Proper aeration, sludge recirculation, and sludge removal are vital to ensuring the system functions efficiently.

Benefits of the Activated Sludge Process

The activated sludge process has several advantages that make it a popular choice for wastewater treatment, here are its benefits:

High Efficiency: The process is highly effective at removing organic pollutants, nutrients (such as nitrogen and phosphorus), and suspended solids from wastewater. It can achieve up to 90-95% reduction in biochemical oxygen demand (BOD) and chemical oxygen demand (COD), ensuring a cleaner effluent.

Flexibility: The activated sludge process can be adapted to various wastewater compositions and treatment objectives. Whether the goal is to remove nutrients or specific industrial pollutants, the process can be customized to meet specific requirements.

Biological Treatment: Unlike chemical treatment methods, the activated sludge process relies on naturally occurring microorganisms, reducing the need for harsh chemicals. This makes it a more environmentally friendly and sustainable option for wastewater treatment.

Reduced Footprint: Advanced configurations of the activated sludge process, such as the use of membrane bioreactors (MBRs) or integrated fixed-film activated sludge (IFAS), can significantly reduce the footprint of the treatment plant while enhancing performance. This is particularly beneficial for urban areas with limited space for treatment facilities.

Sludge Recycling: The return of activated sludge to the aeration tank ensures that the process is efficient and sustainable. The recycling of microorganisms means that new bacteria do not need to be constantly introduced, reducing costs and improving the system’s overall reliability.

Disadvantages of the Activated Sludge Process

The activated sludge process is highly effective for wastewater treatment, it also comes with certain drawbacks that treatment plant operators need to consider. Here are some disadvantages of activated sludge process:

Complex Process Control: The activated sludge process requires careful monitoring and control of factors such as aeration, sludge recirculation, nutrient levels, and microbial health.

Advanced Monitoring Equipment Needed: Plants must invest in automated monitoring and control systems to ensure the process remains stable, which adds to both capital and maintenance costs.

Sensitive to Environmental Conditions: The microorganisms involved in the activated sludge process are sensitive to changes in environmental conditions such as temperature, pH, and the presence of toxic substances. Any significant variation can lead to process failure.

Sludge Bulking Issues: A common problem in the activated sludge process is sludge bulking, where the sludge becomes less dense and settles poorly in the clarifier. This results in a loss of sludge, reduced treatment efficiency, and poor effluent quality.

Activated sludge process in wastewater treatment

The process begins when wastewater enters an aeration tank, where oxygen is continuously supplied to promote microbial growth. The bacteria and other microorganisms in the tank form flocs, commonly known as activated sludge, which digest organic material, converting it into carbon dioxide, water, and biomass. After aeration, the mixture moves to a secondary settling tank, where the sludge settles at the bottom. A portion of this sludge is recycled back to maintain microbial activity, while the excess sludge is removed for further treatment.

The Activated Sludge Process is highly effective in treating both municipal and industrial wastewater, offering benefits like high organic matter removal, adaptability to various flow rates, and the ability to reduce nitrogen and phosphorus levels. However, it requires proper monitoring of aeration, sludge age, and microbial health to ensure optimal performance. This process plays a crucial role in wastewater management, ensuring environmental sustainability and compliance with water quality standards.

Types of Activated Sludge Processes

There are numerous significant variations of the activated sludge process that are used in different treatment plants, depending on the specific needs of the facility and the nature of the wastewater. Some common types include:

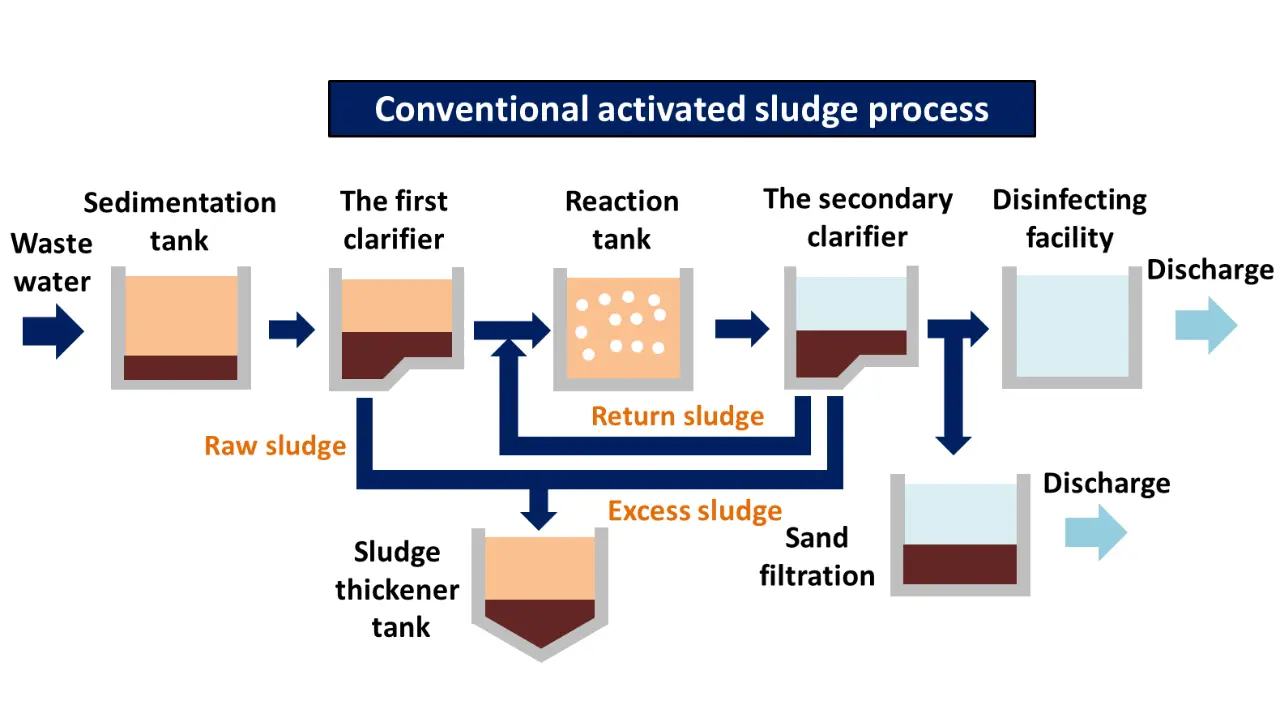

- Conventional Activated Sludge Process: This is the basic form of the process, where wastewater undergoes aeration and settling in a straightforward sequence. It is widely used in municipal treatment plants.

- Extended Aeration: In this variation, the aeration period is prolonged, allowing for the complete oxidation of organic matter and stabilization of the sludge. This method is often used in smaller treatment plants due to its simplicity.

- Sequencing Batch Reactor (SBR): The SBR is a type of activated sludge process where treatment occurs in batches rather than continuously. This allows for more flexibility in managing varying influent loads and different stages of treatment within a single tank.

- Membrane Bioreactor (MBR): MBR technology integrates the activated sludge process with membrane filtration, which enhances the separation of sludge and treated water. This results in a higher quality effluent and reduces the need for large clarifiers.

- Nutrient Removal Systems: Advanced activated sludge processes are often designed to remove specific nutrients like nitrogen and phosphorus. These systems are essential for protecting water bodies from eutrophication and other environmental issues.

Challenges and Considerations

The activated sludge process is highly effective, when it does come with certain challenges that need to be addressed for optimal performance:

- Aeration Costs: Aeration is energy-intensive and can account for a significant portion of the operating costs in wastewater treatment plants. Ensuring efficient aeration systems and optimizing air supply can help reduce energy consumption.

- Sludge Handling: The generation of excess sludge (WAS) requires careful management and disposal. Sludge treatment processes such as digestion, dewatering, and drying are essential to minimize environmental impact and reduce disposal costs.

- Process Control: Maintaining a balance between aeration, sludge recirculation, and nutrient levels is crucial for the system’s efficiency. Process control technologies and automation can help monitor and optimize these variables in real time.

Choose One of The Best Unistar Aquatech Private Limited

The activated sludge process is a cornerstone of modern wastewater treatment, offering an efficient, flexible, and environmentally friendly way to treat sewage and industrial effluent. By leveraging the power of microorganisms, this process can break down harmful pollutants and protect water resources. Despite its challenges, innovations in technology and process design continue to make the activated sludge process a reliable and sustainable solution for wastewater management across the globe.

UNISTAR AQUATECH PVT. LTD. is leading best Waste Water Treatment Plant in India. We have 20+ years of experienced expertise in this field that is why we are the most demanding company for our work quality. For more details contact us now.