Water purification is an important requirement in industries that rely on high-quality water for production and processing. One of the most crucial and widely used methods for water purification is Reverse Osmosis (RO). An Industrial RO Plant is a sophisticated system designed to remove contaminants, impurities, and dissolved solids from water through a semipermeable membrane, making it suitable for industrial applications. In this blog, we will discuss what an Industrial RO Plant is, its working principle, benefits, components, and its importance in various industries.

Read More: LPH in RO Water Purifier

What is Reverse Osmosis (RO)?

Reverse Osmosis (RO) is a water purification process that uses a semipermeable membrane to separate water molecules from dissolved impurities by applying pressure, effectively removing contaminants like salts, minerals, and bacteria from water, leaving behind clean, purified water; essentially, it forces water through the membrane while leaving behind the unwanted substances.

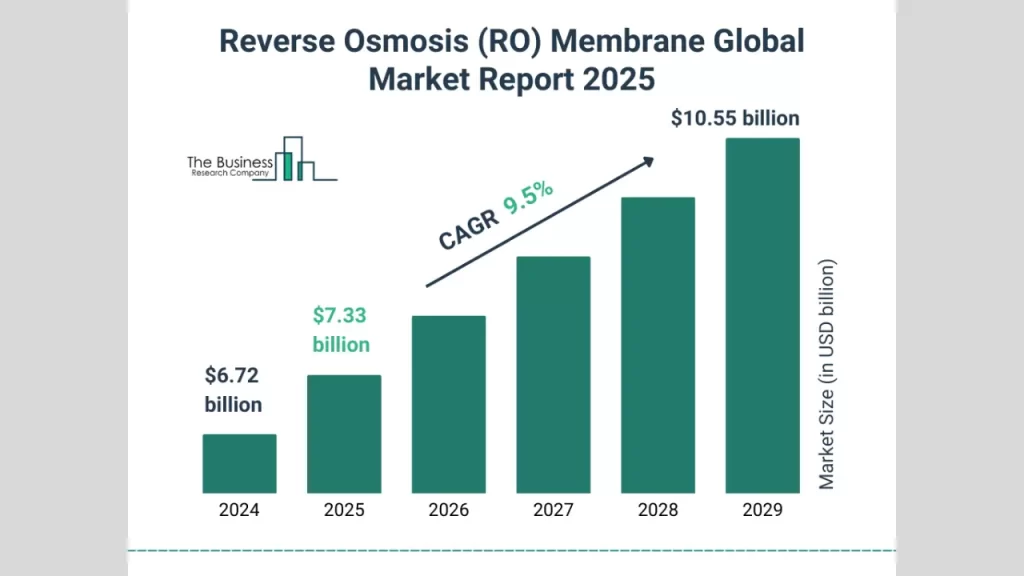

Reverse Osmosis (RO) Membrane Global Market Report

What Is an Industrial RO Plant?

An Industrial RO Plant is a large-scale water purification system that uses reverse osmosis technology to filter out unwanted particles, dissolved salts, and microorganisms from water. It is primarily used in industries such as pharmaceuticals, food & beverage, power generation, textiles, and chemicals where high-purity water is essential for manufacturing processes.

How does the RO Plant Work?

The working of an Industrial RO Plant involves multiple stages to ensure efficient water purification. Below is a step-by-step explanation of how it operates:

Pre-Treatment Stage

Pre-treatment is a preparatory step that can occur in many different contexts, including water treatment, disease management, and recycling. The pre-treatment includes:

- Sand Filtration – Removes suspended solids, dirt, and debris.

- Activated Carbon Filtration – Eliminates chlorine, organic matter, and unwanted odors.

- Water Softening – Reduces hardness by removing calcium and magnesium ions, preventing scaling on the RO membrane.

High-Pressure Pump

After pre-treatment, the water is passed through a high-pressure pump that forces it through the RO membrane. The pressure applied varies depending on the source water quality (brackish or seawater).

Reverse Osmosis Membrane

At the core of the system is the semi-permeable membrane, which filters out dissolved salts, contaminants, and impurities at a microscopic level. The membrane allows only pure water molecules to pass through while rejecting unwanted particles.

Post-Treatment Stage

Post-treatment stage can refer to the staging of cancer after treatment, or the post-treatment process in biochemical or membrane processes. Post-treatment includes:

- UV Sterilization – Eliminates any remaining bacteria or viruses.

- pH Adjustment – Maintains the correct pH level for industrial applications.

- Remineralization – Adds essential minerals to enhance water quality.

Storage and Distribution

Storage and distribution is the process of storing and transporting goods from a manufacturer to the end consumer. It’s a key part of a supply chain.

What Impurities are Removed by the RO plant?

Reverse osmosis (RO) plants remove a wide range of impurities from water, including:

- Dissolved salts: RO removes up to 99% of dissolved salts, such as calcium, magnesium, sodium, chloride, and sulfate

- Microorganisms: RO removes bacteria, viruses, and parasites

- Chemicals: RO removes chlorine, chloramines, herbicides, pesticides, and volatile organic compounds (VOCs)

- Heavy metals: RO removes lead, copper, and other heavy metals

- Other contaminants: RO removes arsenic, radium, fluoride, sulfate, nitrate, and pharmaceuticals

- Organic compounds: RO removes organic compounds, including some pesticides, herbicides, and VOCs

- Protozoa: RO removes protozoa, such as Cryptosporidium and Giardia.

RO systems use a semi-permeable membrane to remove contaminants based on their size and charge.

Industrial Advantages of RO Plants

Industrial Reverse Osmosis (RO) plants offer significant advantages by providing highly purified water, removing nearly all dissolved solids, bacteria, and other contaminants, which is crucial for various manufacturing processes, ensuring product quality and safety while minimizing operational issues related to impure water.

Applications of Industrial RO Plants

- Pharmaceutical Manufacturing: Producing sterile water for drug formulation and cleaning processes.

- Electronics Manufacturing: Providing ultra-pure water for semiconductor production and cleaning processes.

- Food and Beverage Industry: Purifying water used in production processes like beverage making and food washing.

- Power Generation: Producing high-quality water for boiler feedwater in power plants.

- Chemical Manufacturing: Providing clean water for chemical reactions and cleaning processes.

- Wastewater Treatment: Treating industrial wastewater to meet discharge standards.

Choose Best Industrial RO Plant

An Industrial RO Plant is an essential solution for industries requiring high-purity water for their operations. With its advanced filtration technology, cost-effectiveness, and eco-friendly nature, it has become a preferred choice for water treatment in various sectors. We are a leading manufacturer and supplier of high-quality water and waste treatment machinery. We provide sewage treatment plant, effluent treatment plant and more services at affordable prices to our customers. Investing in a quality Industrial RO Plant from Unistar Aquatech Private Limited ensures reliable and efficient water purification to specific industrial needs.

For more information or to get a customized Industrial RO Plant for your business, contact us to learn more about our services!