MBR Technology: The Future of Advanced Sewage Treatment

Water pollution and wastewater management have become major concerns for cities, industries, and residential complexes. Traditional sewage treatment methods are no longer enough to meet modern environmental standards. This is where MBR Technology: The Future of Advanced Sewage Treatment plays an important role. Unistar Aquatech Private Limited provides advanced treatment solutions using modern membrane systems that ensure high-quality treated water suitable for reuse.

In this blog, we will explain the mbr full form, how mbr technology works, its advantages, and why an mbr sewage treatment plant is becoming the preferred choice for sustainable wastewater management.

Sewage Treatment Plant Manufacturer

What is MBR Technology?

MBR stands for Membrane Bioreactor. It is an advanced wastewater treatment process that combines biological treatment with membrane filtration. MBR technology uses microorganisms to break down waste materials and then filters the treated water through special membranes. These membranes remove suspended solids, bacteria, and harmful particles, producing very clean water. Because of its high efficiency, mbr technology in stp (Sewage Treatment Plant) is becoming widely popular in residential societies, commercial buildings, hotels, hospitals, and industries.

How MBR Technology in STP Works

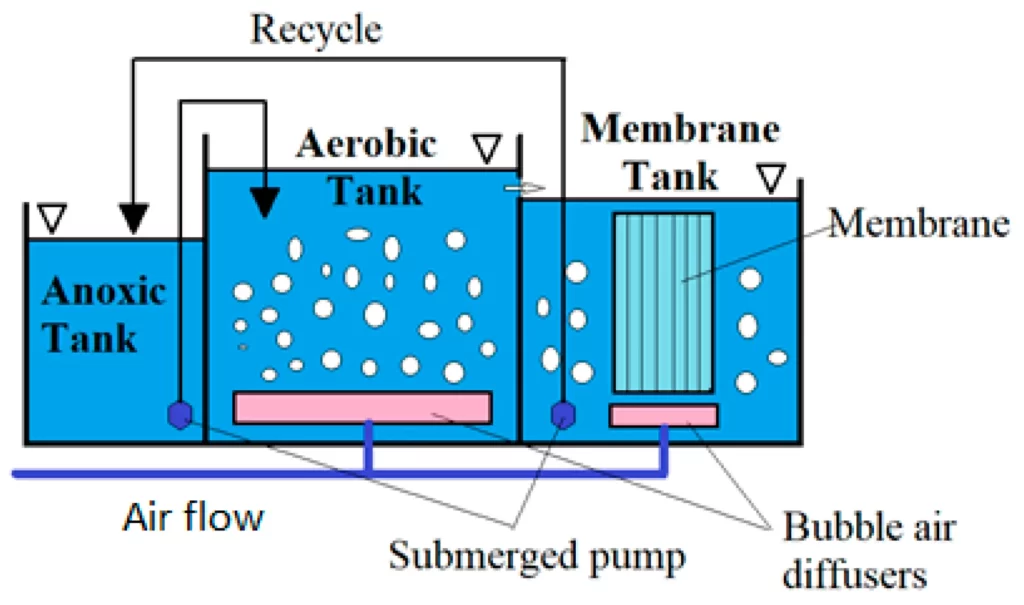

To understand mbr technology in stp, it is important to know its working process. An mbr stp mainly has two major steps: Biological Treatment, Membrane Filtration. In the biological stage, bacteria break down organic waste present in sewage water. This process is similar to traditional activated sludge systems.

In the second stage, instead of using a normal settling tank, the water passes through fine membrane filters. These membranes act as a barrier and remove even very small particles and microorganisms. This combination makes mbr technology in stp much more effective than conventional systems.

Why is the MBR Sewage Treatment Plant Advanced?

An mbr sewage treatment plant is considered more advanced than traditional sewage treatment systems because it produces higher quality treated water. The membrane filtration process removes solids more efficiently and ensures low turbidity.

Some key features of an mbr stp include:

- Compact design

- High treatment efficiency

- Better water quality

- Reduced sludge production

- Easy automation and monitoring

Due to these advantages, many builders and industries prefer installing an mbr sewage treatment plant instead of conventional systems.

Benefits of MBR Technology

1. High-Quality Treated Water- One of the biggest advantages of mbr technology is the superior quality of treated water. The filtered water is almost free from suspended solids and bacteria. It can be reused for gardening, flushing, cooling towers, and other non-drinking purposes.

2. Space Saving Design- An mbr stp requires less space compared to traditional plants because it eliminates the need for large settling tanks. This makes it ideal for residential apartments and commercial complexes where space is limited.

3. Low Sludge Production- In conventional systems, sludge management is a major issue. However, mbr technology in stp reduces sludge production, lowering disposal costs and maintenance efforts.

4. Better Compliance with Environmental Norms- Government regulations for wastewater discharge are becoming stricter. An mbr sewage treatment plant helps industries and housing societies meet pollution control standards easily.

5. Water Reuse Opportunity- Water scarcity is a growing concern. By using mbr technology, treated water can be safely reused, reducing dependency on fresh water sources.

Applications of MBR STP

An mbr stp is widely used in:

- Residential societies

- Hotels and resorts

- Hospitals

- Commercial buildings

- Industrial units

- Educational institutions

Because of the efficiency of mbr technology in stp, it is suitable for both small-scale and large-scale sewage treatment requirements.

Comparison with Conventional STP

When comparing traditional systems with mbr technology, several differences become clear. Conventional STP systems rely on gravity settling to separate sludge from treated water. This process is slower and may not remove fine particles completely. In contrast, mbr sewage treatment plant systems use membrane filtration, which ensures much cleaner output. The treated water quality from an mbr stp is significantly higher and more reliable. This is why experts consider mbr technology the future of advanced sewage treatment.

Maintenance and Operation

Although mbr technology in stp is advanced, it is designed for easy operation. Modern systems come with automation features that reduce manual intervention. Regular cleaning of membranes is required to maintain performance. However, with proper maintenance, an mbr sewage treatment plant can operate efficiently for many years. We design systems that are user-friendly, durable, and energy-efficient.

Why MBR Technology is the Future

The demand for clean water and environmental protection is increasing rapidly. Cities are expanding, industries are growing, and water resources are becoming limited. In such a situation, mbr technology offers a reliable and sustainable solution.

Because of its compact design, high efficiency, and water reuse capability, mbr technology in stp is considered the future of wastewater management. An mbr stp not only treats sewage effectively but also supports water conservation efforts. This makes it an environmentally responsible choice.

Choosing the Right MBR Sewage Treatment Plant

When selecting an mbr sewage treatment plant, it is important to consider:

- Treatment capacity

- Quality of membranes

- Energy consumption

- Automation features

- After-sales service

Unistar Aquatech Private Limited provides customized mbr stp solutions designed according to specific site requirements. Our systems are built with high-quality components to ensure long-lasting performance and reliability.

Conclusion

MBR Technology: The Future of Advanced Sewage Treatment is not just a modern concept but a practical solution for today’s wastewater challenges. Understanding the mbr full form and how mbr technology in stp works helps industries and residential projects make informed decisions.

With benefits like compact design, superior water quality, reduced sludge, and water reuse potential, an mbr sewage treatment plant stands out as a smart investment for sustainable development.

If you are planning to install a high-performance sewage treatment system, choosing an advanced mbr stp from Unistar Aquatech ensures efficiency, environmental compliance, and long-term value.